Let’s face it, how often do you think about the footbed of your favorite running shoe? Runners love to talk about a shoe’s outsole, midsole, and upper, but the insole, a critical component of a shoe’s comfort, is often overlooked.

Part of this may be due to the fact that leading footbed manufacturer OrthoLite has been providing more than 450-plus top footwear brands with insoles that work so well that people forget how necessary they are for a shoe to perform. Celebrating their 25th anniversary in 2022, the company is proud to be the largest manufacturer and supplier of insoles for all types of shoes, including athletic, running, comfort, lifestyle, and fashion. More than 500 million pairs of shoes use their insoles each year, so the chances are high that several of the running shoes in your closet sport OrthoLite insoles.

But OrthoLite doesn’t only focus on creating comfortable insoles, the company is also dedicated to environmental sustainability. Since its beginnings, OrthoLite has worked hard to find ways to reduce waste and energy use in its manufacturing processes, all while still creating highly functional and comfortable products. Shoe brands, including adidas, Asics, New Balance, Brooks, Reebok, HOKA, and Salomon, have benefitted from OrthoLite’s commitment to comfort, performance, and sustainability.

A History of Environmentally Friendly Practices

Since day one, OrthoLite has been dedicated to the continual improvement of its sustainable manufacturing processes worldwide. Not only does the brand want to create great products, but OrthoLite seeks to do it with minimal environmental impact.

Because OrthoLite is a vertically integrated company that owns its factories, it has been able to incorporate environmentally friendly practices to reduce waste and energy use. The company’s commitment to increasing operational efficiencies, using solar panels for energy, and having a wastewater treatment facility has earned the company scores above the 90th percentile from the Higg Index, a standard for assessing the environmental sustainability of a supply chain for a product.

OrthoLite recently earned Global Recycled Standard certification, a standard for tracking and verifying a product’s recycled materials, at its Vietnam facility, which underscores OrthoLite’s active commitment to improving sustainable operations. Its factories also have a Zero Waste initiative and their own recycling facilities. The company is actively involved in the research and development of sustainable manufacturing practices. The goal is to minimize the use of toxic chemicals and additives in their processes to protect the environment.

When OrthoLite first started manufacturing insoles in 1997, the company’s top goal was to create more comfortable shoes. A significant upgrade from the basic foam insoles that existed at the time, OrthoLite’s replacements were made of open-cell polyurethane foam. This new material helped keep feet cooler and drier. Early on, the company committed itself to developing sustainable manufacturing practices. OrthoLite focused on finding circular manufacturing solutions where everything that went into their products could get recycled or composted. Its ultimate goal still remains zero waste.

Modern Sustainable Insole Technology

By creating trust-based relationships with the leading shoe brands, OrthoLite is able to customize its insoles for the specific needs of various shoe manufacturers. The company has the largest portfolio of proprietary eco-technologies for insoles in the industry. With these options, OrthoLite can create products with various levels of eco-content, ranging from 5% to 98%. By working closely with companies, the brand is able to meet the specific performance and sustainability needs that brands have for different types of shoes.

OrthoLite also has two new options for sustainably created insoles, the HybridPlus-Recycled™ and the HybridPlus-Bio™. Both new models of insoles have high levels of recycled materials.

The HybridPlus-Recycled™ insole contains 50% recycled content, including recycled rubber powder and polyurethane foam. The HybridPlus-Bio™ goes a step further, using 7% bio-oil in the insole to minimize the petroleum used in the manufacturing of the product.

The two insoles are among the latest innovations to come from OrthoLite’s team. The company continues to pursue the goal of repurposing waste materials from its manufacturing processes. And while the new insoles are made with new materials, OrthoLite refuses to compromise on comfort and performance.

OrthoLite Cirql: The Next Generation of Sustainable Footwear Components

Many shoe midsoles and insoles are made with EVA foam, a non-recyclable material. Created with non-renewable chemical compounds that don’t biodegrade, often called “forever chemicals,” EVA is not particularly environmentally friendly.

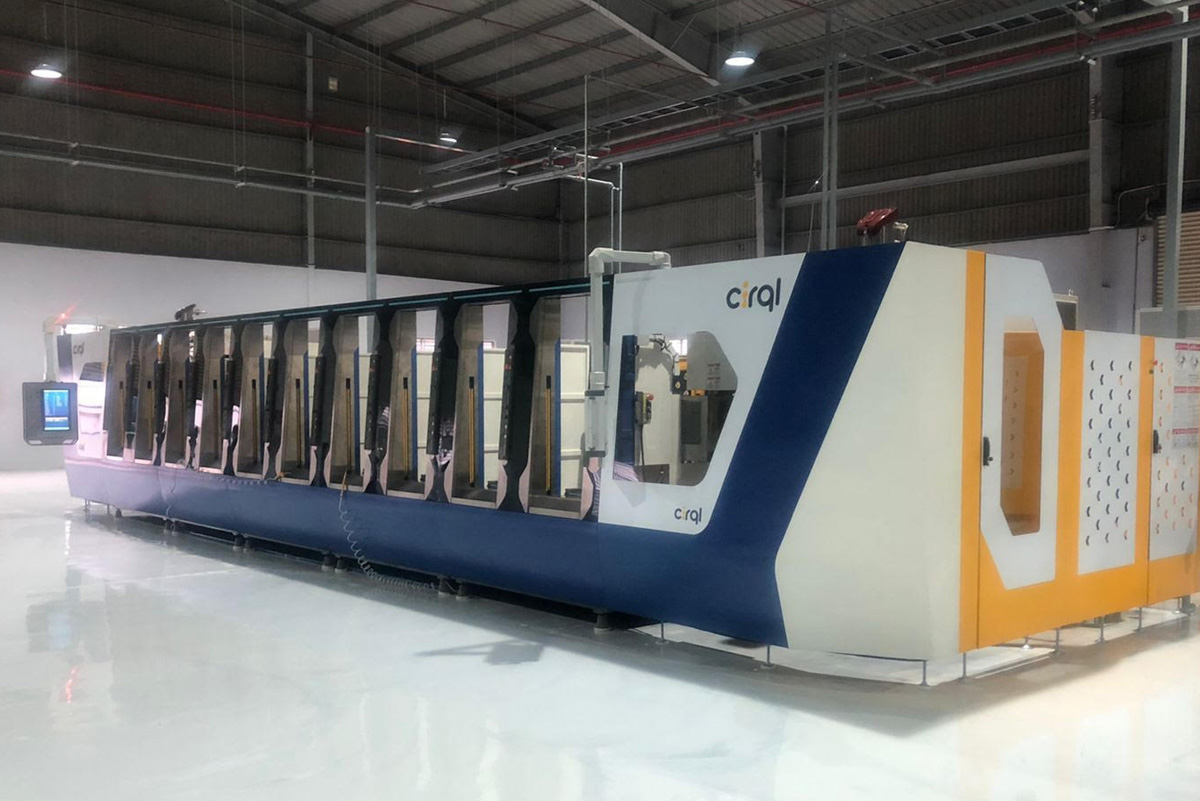

OrthoLite focuses on innovation and its global development team prides itself in bringing new concepts to life for its brand partners. For example, OrthoLite had a better idea for creating foam for midsoles, developing Cirql, a soil-to-soil circular product solution. This foam product, announced in early 2022 and entering into initial development with brand partners in 2023, is free from EVA plastics and is created from plant and other biodegradable materials. Even the processing of the material is done in a zero-waste and chemical-free manner.

After a shoe wears out, the Cirql material will either biodegrade or can be recycled, leaving behind no microplastics or other harmful chemicals to pollute the earth. This advancement in foam technology has the potential to make the shoe manufacturing process much more sustainable by helping footwear brands elevate their sustainability efforts through cleaner manufacturing and using a true soil-to-soil product.

The Future of Insoles is Comfortable and Sustainable

With incredible growth in the running industry, it’s important for brands to think about sustainable practices at least as much as they are thinking of creating a comfortable product.

OrthoLite is leading the way, providing options for top brands to create shoes in a sustainable manner. OrthoLite believes that environmentally circular product manufacturing, where everything that goes into creating a product is biodegradable or recyclable, is the way of the future. OrthoLite footbeds reflect the company’s commitment to the environment and the advancement of sustainable practices.

So the next time you notice that comfortable OrthoLite insole in your favorite running shoe, you can also consider that it’s an insole made with the future of your prized trails in mind.